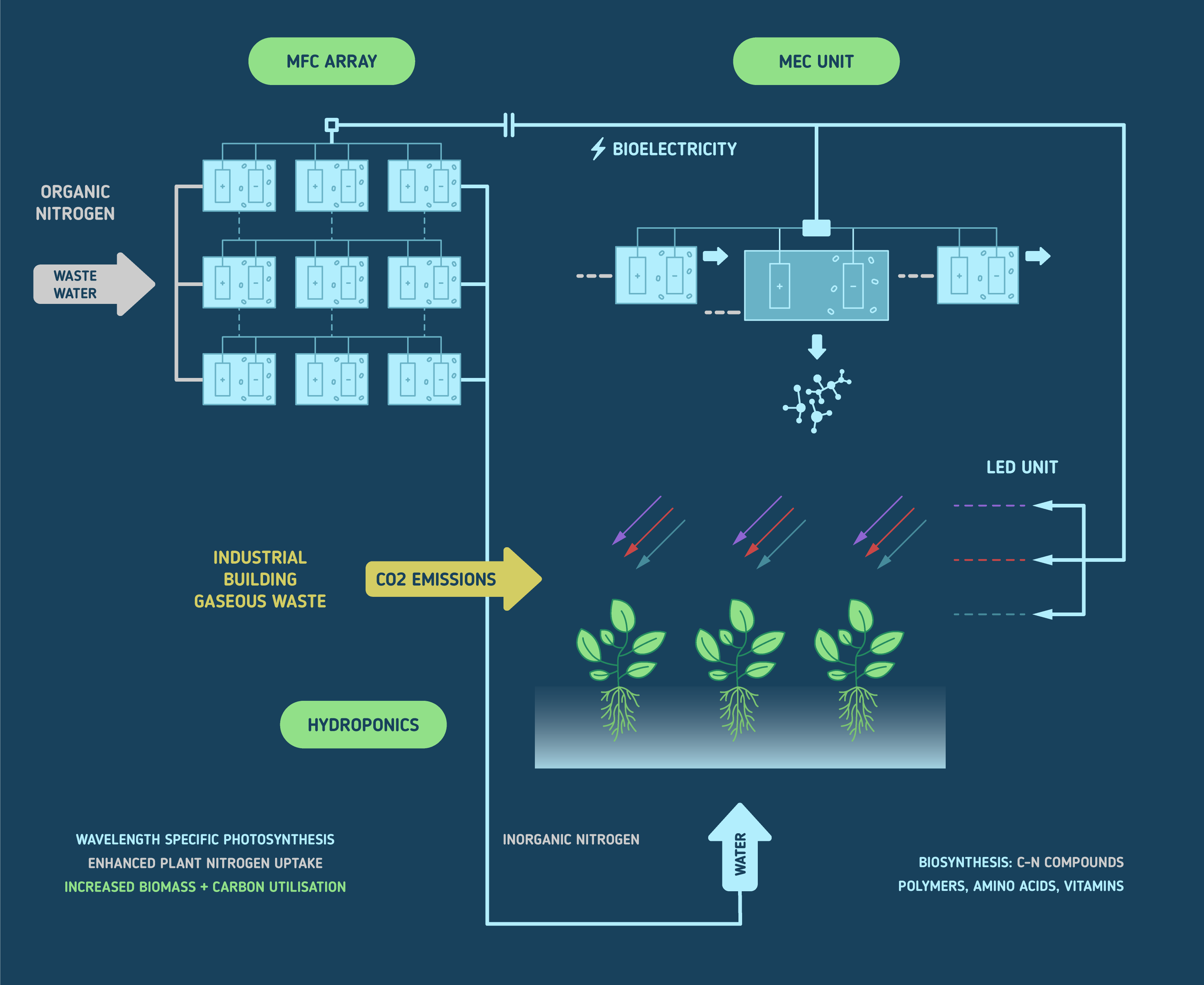

Mi-Hy represents an innovative approach to hydroponics, waste treatment, and energy generation by integrating processes which historically have been separate into a single ecosystem. This eliminates the need for external (fossil-fuel-based) energy or carbon and nitrogen sources. The novel integrated platform consists of the following processes:

Bioelectricity-generating MFCs: These aim to achieve a benchmark of 1mW per 1 mL feedstock, setting a new standard for Microbial Fuel Cell (MFC) technology. The MFCs capture CO2 while simultaneously reducing nitrogen (N) and phosphorous (P) from wastewaters.

Wavelength-specific hydroponics LEDs: These are driven by artificial intelligence (AI) in regulated phased cycles of activity and remainder. This approach enhances photosynthesis with reduced energy demand.

Hydroponics system: This component of Mi-Hy produces biomolecules, including acetate and 2,3 butanediol (2,3-BDO).

Microbial electrolysis cell (MEC): This serves as a workhorse, powered to perform microbial electrosynthesis (MES) from wastewater, similar to the MFC. This process occurs during darkness when photosynthesis is not taking place.

Wastewaters feed the MFC array & CO2 feeds the plants in hydroponics. The MFC in turn generates electricity for the LEDs that supply hydroponic plants with light & inorganic nutrients from the wastewater. As the MEC is working when there is no need of electricity (i.e., when the plants are “not photosynthesising”) it is possible to synthetize value-added molecules in the electrode chamber & collection with biocompatible base compounds (e.g., natural rubber). Additionally, the aerial parts of the hydroponics fruit can be harvested several times throughout the year depending on the cycle of the plant.